Hydrogen isn't clean,

it's produced by burning fossil fuels.

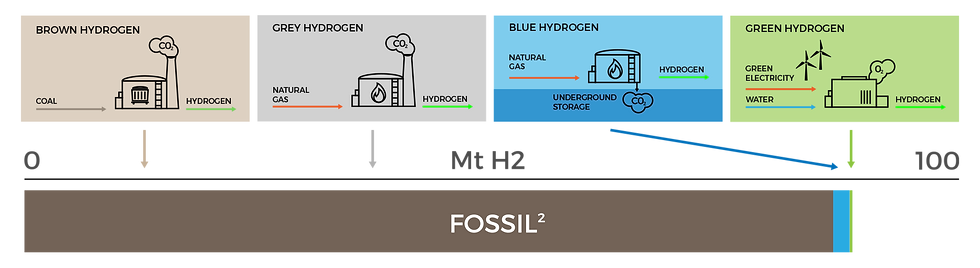

Almost all of today’s hydrogen is produced using fossil fuels—not because it’s the only way, but because it’s currently the cheapest. We call this ‘brown’ hydrogen.

Green hydrogen is the product of electrolysis (on water) that is powered by renewable energy.

In the coming years, as the cost of both renewable energy and electrolysers falls, green hydrogen will become more competitive.

And if we can supply consumers and businesses with a viable, green competitor to fossil fuels there’s every chance they’ll make the change.

Today, 95 per cent of the world’s

hydrogen is produced using natural gas in a process called steam methane reforming (SMR), which emits significant amounts of CO2. We call this ‘grey’ hydrogen.

Current global hydrogen production categorised by colour

Green hydrogen production makes up just 0.1% of global hydrogen production1

However, if the carbon dioxide is captured and stored through carbon capture and storage (CCS), then what’s produced is low-carbon or ‘blue’ hydrogen. It’s considered to be ‘clean’.

But there are other ways to produce hydrogen.

Another ‘clean’ method, is on everyone’s lips …

GREEN HYDROGEN

Hydrogen can also be produced by electrolysis (of water). When the electricity used in the process comes from renewable sources, that hydrogen is referred to as ‘green’ hydrogen.

Extracting hydrogen from water through electrolysis

Solar, wind or tidal energy

Water is split into hydrogen and oxygen using an electrolyser and electric current

Hydrogen used as a fuel or storage locally, or converted into a derivative for transport

Ref: Australian REZ conference_Amal.pdf

Electrolysis is by no means a new technology—it’s been around for more than 200 years. What’s new is the idea of using renewable power to drive large-scale electrolysers and produce lots of hydrogen.

However, compared to the overall amount of hydrogen produced, only a very small proportion is currently produced by electrolysis. That’s because, right now, electrolysis is a more expensive way to produce hydrogen compared to using fossil fuels.

A single kilogram of green hydrogen produced today would cost USD $3-8, compared to USD $0.5-1.7 for 1 kg of hydrogen produced through SMR.

But, in the not-too-distant future, we’ll see prices fall significantly.

Quite simply, the key factors that govern the price of renewable hydrogen are the cost of electricity and the cost of the electrolyser.

As far as electricity is concerned, the International Energy Agency says that solar PV is now the cheapest electricity in history.

As for the cost of electrolysers; as the scale increases, the price will fall.

But cost isn't the only issue...

Producing 1kg of hydrogen through electrolysis ‘directly’ requires 10-12 litres of water. In addition, it would need between 50% and 300% more water to cool the electrolyser.

Although Australia has excellent natural resources, one thing the country doesn’t always have an abundance of is water.

In fact, according to the World Resources Institute (WRI), Australia is under medium-to-high water stress.

To put that into context, in order to produce the projected amount of hydrogen required for export, we would need to find a water source equivalent to Australia’s total annual drinking water consumption.

However, this isn’t a showstopper; we can potentially use wastewater and seawater. Much of our wastewater goes unused and we have desalination plants in Sydney, Perth, Melbourne, Adelaide and the Gold Coast.

Research is also being conducted into using seawater directly in the electrolysis process.

Imagine that for a moment: a floating wind tower feeds electricity into the grid when demand is high and drives the electrolysis of seawater to produce hydrogen when demand is low.

So just how realistic is the idea of green hydrogen and is it essential to global net zero emissions?

"From my perspective, there can be little doubt that green hydrogen has an important role to play in the achievement of net-zero plans across the world. It is, after all, an emissions-free fuel and a renewable energy carrier. But, make no mistake, the sheer scale of what needs to be done means a transition to a green-hydrogen-powered world is not going to happen overnight. Instead, we’ll see continuous growth in renewable hydrogen generation until the level of supply reaches a critical mass.

In the meantime, we’ll need to grow the demand for hydrogen and, equally, we’ll need to ensure there is sufficient and cost-effective supply. There’s little point in industries across the world transitioning to hydrogen if there’s not enough to go around or it’s so expensive that it reduces their ability to compete in the market. In other words, the transition will need to involve other types of hydrogen—obviously, I hope ‘clean’ types—which will have a role to play in getting us to where we need to be.”

We posed this question and others to UNSW Scientia Professor Rose Amal, a hydrogen expert and the Co-Director of GlobH2E—the ARC Industrial Transformation Training Centre for the Global Hydrogen Economy— and lead of NSW Power-to-X.

Can we really produce green hydrogen at scale?

“Why not? We’re already seeing plenty of proposals for GW-scale green-hydrogen production plants. And, from an investment point of view, hydrogen ticks plenty of boxes for renewable generators. Not only can they supply electricity to the grid, but they can also produce—and sell—hydrogen in many different forms.

It just makes sense to be producing hydrogen this way. So, the answer to ‘can’ we do it, is very firmly a yes. Will we do it, is perhaps another question.

There is a general consensus that A$2/kg is a feasible target price for ‘clean’ hydrogen by 2030 and there’s some suggestion we will reach that target far earlier. At that point, the only thing standing in the way of ‘clean’ hydrogen is the users themselves.

In terms of why an individual would use hydrogen at home, there’s clearly a philosophical benefit. If you care about the future of the planet and have an affordable, environmentally friendly alternative, why wouldn’t you take it? The big question is whether we can make it affordable.

It would be easy to be sceptical and say that businesses will only transition if they see the financial benefit, but don’t forget that a fifth of the world’s largest companies have already committed to being net-zero. What we’ll be offering them is a viable, green competitor to fossil fuels. That being the case, why wouldn’t they choose to make a change?”